The importance of sterile supply logistics in the reprocessing process

Sterile goods logistics

The transport of medical devices in the medical device cycle is crucial to the success of reprocessing and is of decisive importance for maintaining the value of sterile goods.

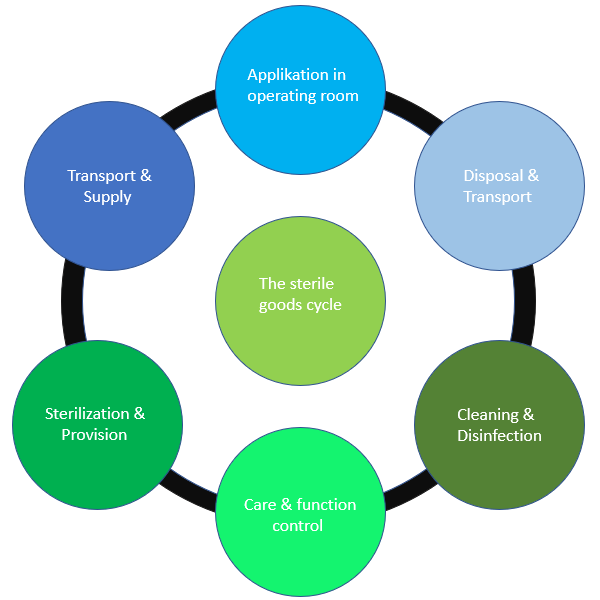

It is not only the transport of sterile goods from the operating theatre to the reprocessing site that needs to be coordinated and defined, but also all transport routes that a medical device passes through as part of the sterile goods cycle. The time component plays a key role here, so that all patients can be treated as planned and the medical devices are available again at the place of use in good time after reprocessing.

The process described above is referred to as sterile supply logistics. By definition, logistics ensures the availability of the right goods, in the right quantity, in the right condition, in the right place, at the right time, for the right customer, at the right cost (Seven Rights definition according to Plowman).

A distinction must also be made between internal and external logistics processes in sterile supplies logistics.

Internal sterile processing refers to the processing of medical devices within the hospital. In external reprocessing, medical devices are reprocessed by an external service provider, resulting in transport routes outside the place of use.

Due to the complexity of the sterile supply logistics process, problems can arise during transport for both internal and external reprocessing of medical devices.

- Insufficient regulation of responsibilities

- Incorrect prioritisation of pick-up and delivery services

- Missing or incorrect accompanying and transport documents

- Lack of infection protection for employees during transport (e.g. missing or inadequate protective equipment)

- Insufficient transport security

- Lack of labelling of infectious material in accordance with IFSG

- Collection of instruments to be reprocessed and associated untimely reprocessing of medical devices

- Distance from the place of use to the place of reprocessing in the case of external reprocessing

- Transport time for external reprocessing

- Temperature influences

In order to achieve an optimal sterile goods logistics process, the potential problems described above must be minimised as far as possible. An effective logistics process for medical devices brings economic benefits. For example, equipment in the AEMP is continuously utilised and AEMP staff can be optimally scheduled.

Not only economically, but also legally, the transport and logistics process for medical devices must be carried out in such a way that all activities are reproducible so that patients, users and third parties are not harmed. Accordingly, all activities involved in sterile goods logistics must be recorded in a quality management system in the form of process and work instructions. The QM system thus regulates the interface transport of medical devices in the reprocessing process.

The following points should be observed:

- Observance of the reprocessing requirements (reprocessing as quickly as possible to ensure the cleanability of the medical devices and thus the fastest possible transport of the instruments to be sterilised and return transport to the user)

- Observance of the user’s requirements (availability of harmless instruments at the place of use (operating theatre) at the right time)

- Creation of prerequisites for transport (e.g. safe storage systems, transport systems, preparation of transport systems, suitable vehicle for external transport)

- Definition of the transport process (e.g. transport times, transport routes, communication channels / contact persons, visible labelling of transport containers, pick-up locations, delivery locations)

- Information and training (trained personnel as a basic prerequisite for smooth sterile supplies logistics in the AEMP)

Detailed information on sterile supply logistics can also be found in the recommendation of the DGSV “Quality” working group (73) – Logistics in the reprocessing of medical devices:

The complexity of logistics in AEMP alone shows how strongly the high-quality reprocessing of sterile supplies depends on a functioning process that protects patients, users and third parties and promotes the value retention of medical devices, thereby also keeping the costs of sterile supply reprocessing at a reasonable level.

As an independent consultant with many years of experience and expertise in the field of sterile processing, we will be happy to advise you. As part of our service portfolio, we take an independent look at your processes and make recommendations for optimising and improving your sterile processing process – to protect your patients and employees and to maintain or improve your profitability in the AEMP.

Further facts and figures can be found in our business case for sterile processing:

Whether AEMP in a large hospital or reprocessing in outpatient centres – we offer you the right individual concept for your sterile processing.

In order to keep your staff up to date with the latest knowledge and technology at all times, we have a comprehensive range of seminars in our training portfolio, which gives you the opportunity to select the seminars individually according to your needs.