Water treatment for commercial laundries, monitoring system Research project

Water treatment research project: Intelligent monitoring system for commercial laundries

Research project – IMPRESS (Intelligent monitoring system for increasing process quality and resource efficiency in commercial laundries)

As a globally active company in the field of innovative water treatment, we feel committed to our slogan Tradition and Future at Your Side.

In addition to the current day-to-day tasks, employees of our company accompany a wide variety of research projects and experimental setups on current issues of process optimization.

Within the period from 01.10.2019 to 31.03.2022, under the leadership of:

carried out the IMPRESS project.

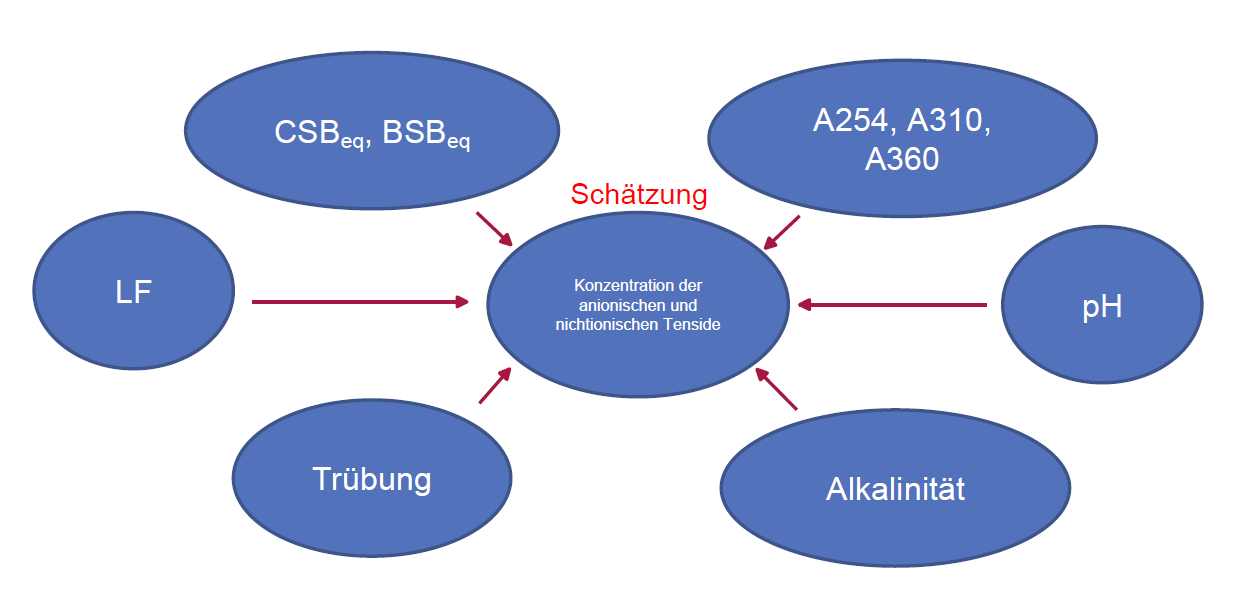

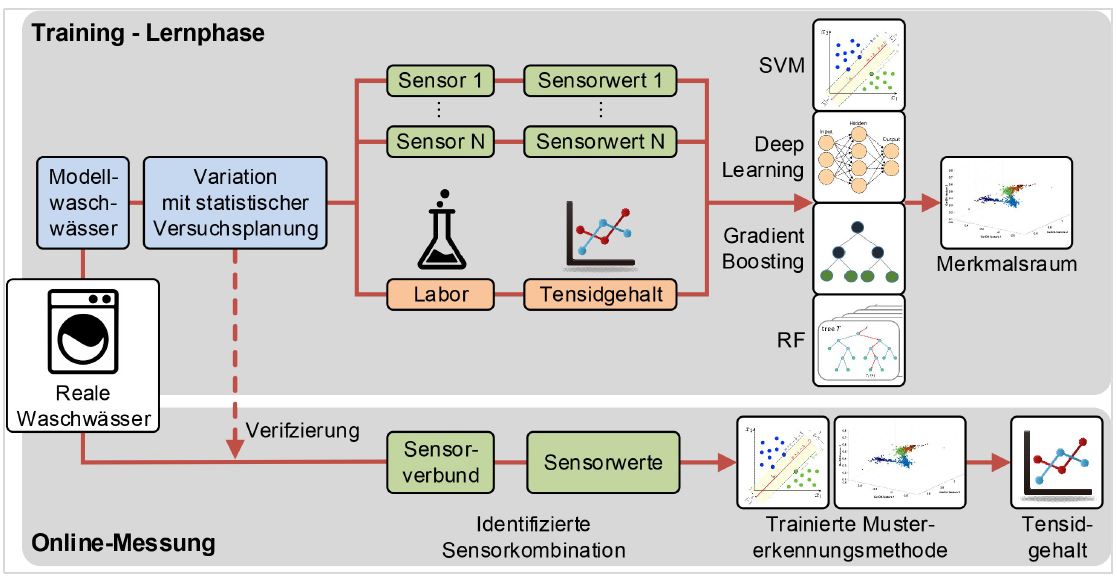

The objective of the research project is the development of an AI-based sensor for online detection of the concentration of anionic and non-ionic surfactants for a

Intelligent, flexible monitoring of washing and wastewater recycling processes in laundries.

In the first phase of the project, the parameters for the sensory AI concept were defined. The objective here was to define an initial parameter matrix in order to test the research approach in a laboratory test setup.

As a result of the considerations by the participating companies, industrial partners and research institutions, the parameters CSBeq, BSBeq, conductivity, turbidity, alkalinity, pH value and an absorption measurement at 254, 310 and 360 nm were defined for the test setup.

Image source: Presentation Hohenstein Institut für Textilinnovation GmbH on the second committee meeting accompanying the project.

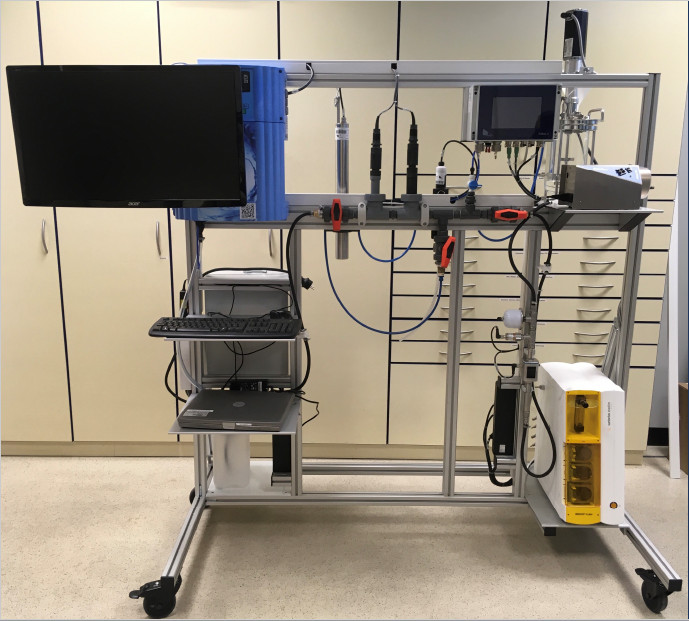

Image: Overview of the sensor network in the laboratory test setup at the Hohenstein Institute (Image source: Presentation by the Hohenstein Institute for Textile Innovation GmbH at the second committee meeting accompanying the project).

Surfactants are essential components of detergents and cleaning agents.

Often the mode of action of surfactants in the washing and water treatment process is unclear due to e.g. mixing or interaction with dirt and other components.

This results, among other things, in inadequate process quality and additional costs caused, for example, by blocking of the membranes. Furthermore, potentials regarding resource conservation and possible process optimization are not exploited.

In the experimental setup, a bench-top bioreactor is used to feed the “model wash liquor”, which is then aspirated by means of a rotor hose pump and fed to the measuring mimic.

A relative pressure sensor, a magnetic inductive flow meter and a pulsation damper to ensure a homogeneous volume flow are used to monitor/ensure process stability.

All measured data are read in and processed via the Lab-View program.

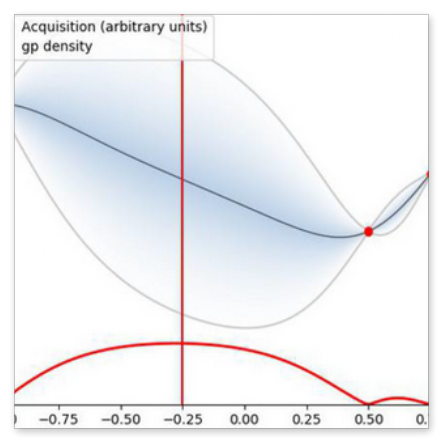

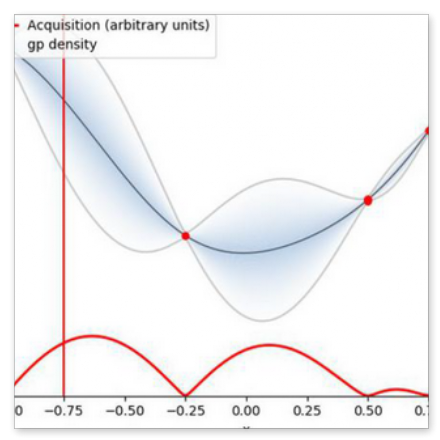

By carrying out series of N measurements, a mathematical model is used to determine an algorithm that should be used to predict the concentration of surfactants in the process.

Image source: Presentation Hahn Schickard Gesellschaft on the second project-related committee meeting

Within the scope of the scientific analysis, model process waters are set up under laboratory conditions using various scenarios and used for the verification of the sensor network.

The aim is to achieve a realistic simulation of the process water compositions to be expected in practice in order to be able to evaluate the suitability of the measurement technology used for determining the relevant individual parameters of the sensor network.

Dipl.-Ing. (FH)

Karsten Hesse

Image source: Presentation Hahn Schickard Gesellschaft on the second project-related committee meeting

The IGF project 20792N of the research association Hahn-Schickard-Gesellschaft für angewandte Forschung e.V.. Reinhardtstraße 12 – 14, 10117 Berlin was funded by the Federal Ministry for Economic Affairs and Energy via the AiF within the framework of the program for the promotion of joint industrial research and development (IGF) on the basis of a resolution of the German Bundestag.