Sterile and ultrapure water treatment for the hospital and the laboratory

Sustainable sterile water treatment in hospitals

Protecting natural water resources is also the responsibility of the healthcare system and hospital operators.

Sustainable water management in hospitals can address the following points, among others:

• for stationary sanitary facilities

• in the operating and treatment area

• in the laboratory

• in therapeutic baths

• in the laundry and kitchen

• for technical water treatment

Sterile and ultra-pure water treatment through highest measurement standards

Laws, standards and guidelines regulate sterile steam generation in hospitals.

High quality standards for process water and cleaning procedures help to increase patient safety and prevent infections.

Standards and guidelines such as the European standard DIN EN 285:2016 on sterile steam generation regulate water quality for clinical applications in hospitals.

The quality of the feed water for pure steam generation and generation of ultrapure water is subject to the following limits for the CSSD:

- Evaporation residue ≤ 1.0 mg/kg ≤ 10 mg/l

- Silicon, SiO2 ≤ 0.1 mg/kg ≤ 1.0 mg/l

- Iron ≤ 0.1 mg/kg ≤ 0.2 mg/l

- Cadmium ≤ 0.005 mg/kg ≤ 0.005 mg/l

- Lead ≤ 0.05 mg/l

- Traces of heavy metals except iron, cadmium, lead ≤ 0.1 mg/kg

- Chlorides (Cl) ≤ 2 mg/l

- Phosphates (P2O5) ≤ 0.5 mg/l

- Conductivity (at 20 °C) ≤ 15 µS/cm

- pH value 5 – 7

- Hardness ≤ 0.02 mmol/l

The steam used and the feed water must meet the specified limits of the European standard DIN EN 285.

If these are exceeded, surface changes can occur on the surgical instruments, such as discoloration, water spots or corrosion, which can lead to permanent damage to the instruments.

Therefore, demineralized water is normally used for sterilization in order to keep the quality requirements within the prescribed range.

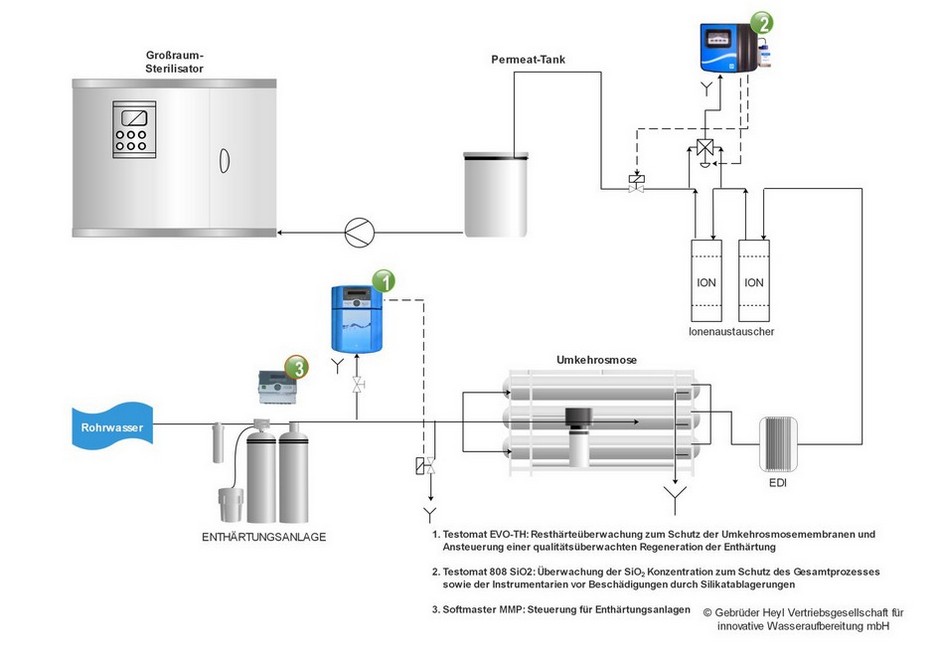

Schematic representation of the ultrapure water treatment of the central sterilization in hospitals

Silicate content and conductivity

In order to obtain reproducibly stain-free instruments, the silicate content should be permanently below 0.4 mg/l.

Quality monitoring of demineralized water by electrical conductivity control is not sufficient for identification because silica does not impart conductivity to water.

And now?

- Current recommended values are not suitable!

- Practice shows that the limit values have to be set even lower and have to be adjusted in terms of process engineering.

- Plant technology is designed according to recommendation values and is therefore OK according to the standard, but does not take into account the latest findings and the overall process.

The process is validated 2 x per year only! (Only twice is analyzed!); Manipulation very easy (e.g. change of the blending bed shortly before validation).

Problem solution for poor

Instrument quality

Other findings:

In practice, the operators of clean steam generators hardly maintain them (blowdown and desalination are often not carried out properly).

This leads to an accumulation of impurities in the washer-disinfector and thus, in the worst case, to an entry into the sterile process.

Damage to the washer-disinfector (corrosion, etc.)

Why is this only now emerging?

For the first time, the entire process was examined in a qualified manner and initial assumptions were confirmed with laboratory tests.

Problem instrument quality

Water treatment for hospitals for the optimal sterilization process

Heylneomeris measurement and control technology meets the highest industrial standards in this area while complying with all legal requirements.