Cooling tower process blowdown analysis technology

The desalination system for cooling towers sustainably prevents damage

As a rule, heated cooling water produced in power plants or industrial processes is recooled in cooling towers. For economic and ecological reasons, particular attention must be paid here to the consumption of cooling water, energy consumption and protection of the plant.

Untreated or only partially softened water, which is used as feed water for cooling water circuits or air washers, very often leads to difficulties with:

- Biological deposits caused by slime bacteria and algae (contamination)

- Corrosion of metallic materials

- Lime deposits

To counteract this, automatic monitoring and conditioning of the cooling circuit water is necessary.

- The desalination can be controlled either conductivity-dependent or TDS-dependent. An interlock of the desalination after a biocide dosing is provided. The blowdown duration can be monitored.

- The biocide dosing can optionally take place after a certain number of days or regularly on certain weekdays at a fixed time. Optionally, pre-salting is possible.

- For quantity-proportional inhibitor dosing, various setting options for dosing time and dosing duration are available.

- The circulation can optionally take place after a certain number of days or regularly on certain days of the week at a fixed time.

In addition, limit values, e.g. for temperature (min. and max.) or pH value (min. and max.) can be monitored.

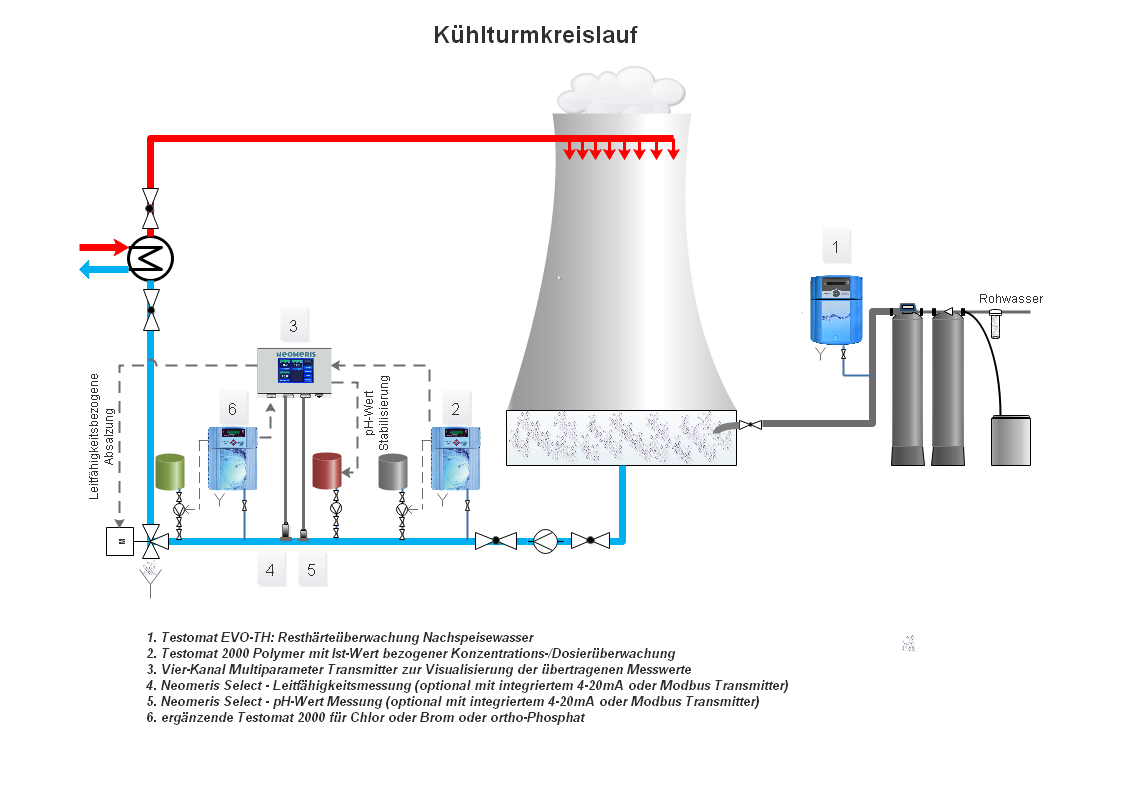

Schematic representation of a desalination plant for cooling towers.

Amortization of a desalination plant for cooling towers

Without water treatment, the costs for the higher energy consumption, downtimes of the plant, maintenance and repair costs easily amount to significantly more than 10,000 € per year.

The ROI of the plant investment is usually achieved within one year.

Request individual offer directly online

Request an offer directly via the watch list.

After consultation with you, we will be happy to create your individual offer with these products or products that match your needs.

Our experts will contact you prepared.