Electrical conductivity (sigma σ)

The electrical conductivity is a physical quantity that describes the extent to which a substance conducts electricity. It determines whether a substance is suitable as an insulator or as an electrical conductor. It is also used to identify substances. The usual measured values for conductivity are: < 1 µS/cm for ultrapure water, approx. 1000 µ/S/cm (1 mS/cm) for drinking water and > 100 mS/cm for cleaning solutions.

Most of the substances dissolved in water are salts. The lower the measured value, the fewer dissolved substances (primarily salts) are dissolved in the water. Conversely, a high conductivity means a high salt concentration.

An electric current flows depending on the conductivity. At constant voltage, the current increases proportionally with the conductivity.

Conductivity probes consist of a pair of electrodes. The cell constant is an essential property of the probe and reflects the relation of electrode spacing to electrode areas. Because the conductivity between the electrodes is affected by the cell geometry, the cross-section and spacing of the electrodes must be considered to standardize the conductivity measurement.

Depending on the area of application, different conductivity measurement principles are used. A distinction is made between conductive and inductive measurement.

The electrodes of a conductive sensor consist of conductive materials (e.g. metals such as platinum, gold, steel, titanium, and non-metals such as graphite). These are in direct contact with water or the measurement solution. The primary parameters measured are voltage and applied current. From this, according to Ohm’s law, the resistance can be calculated measured in ohms [Ω]) or as the reciprocal – the conductance G (measured in Siemens [S]). With conductive sensors, even conductivities of 1 µS/cm can be measured.

Inductive sensors have two electromagnetic coils enclosed in a plastic jacket. By applying an AC voltage to one coil (driving coil), a voltage is generated in the other coil (receiving coil). The conductivity of the medium has a strong influence on the level of the induced current. Due to the plastic coating, inductive sensors can also be used in aggressive media, since the measurement-relevant part (coils) is protected from external influences by this. Inductive sensors can be used from a conductivity of > 15 µS/cm.

The basic principle of an electrochemical sensor consists of at least two electrodes (measuring and counter electrode), which have contact with each other in different ways:

- on the one hand via an electrically conductive medium (electrolyte, i.e. liquid as ion conductor),

- on the other hand via an external electrical circuit (electron conductor).

The electrodes are made of special material and have a catalytic effect, so that certain chemical reactions take place at the so-called 3-phase boundary, where gas, catalyst and electrolyte are present.

The term measuring equipment covers the complete instrumentation used for conductivity measurement, consisting of:

- Conductivity transmitter (sensor),

- Immersion or flow-through fitting,

- transmitter (measuring device),

- Connection cable

The transmitter has the task of processing the sensor signal. The sensor signal is converted into a standard signal (e.g. 4 … 20 mA) and can thus be passed on directly to a downstream control system (microcontroller, PLC) or metering unit. This makes it possible, for example, to implement simple processes such as desalination in the cooling tower.

When calibrating, the following must be observed: Test resistors are available to check the proper functioning of the transmitter. These resistors simulate a defined conductivity value. When calibrating a measuring instrument, it can be determined whether and to what extent the measurement results differ from the actual values.

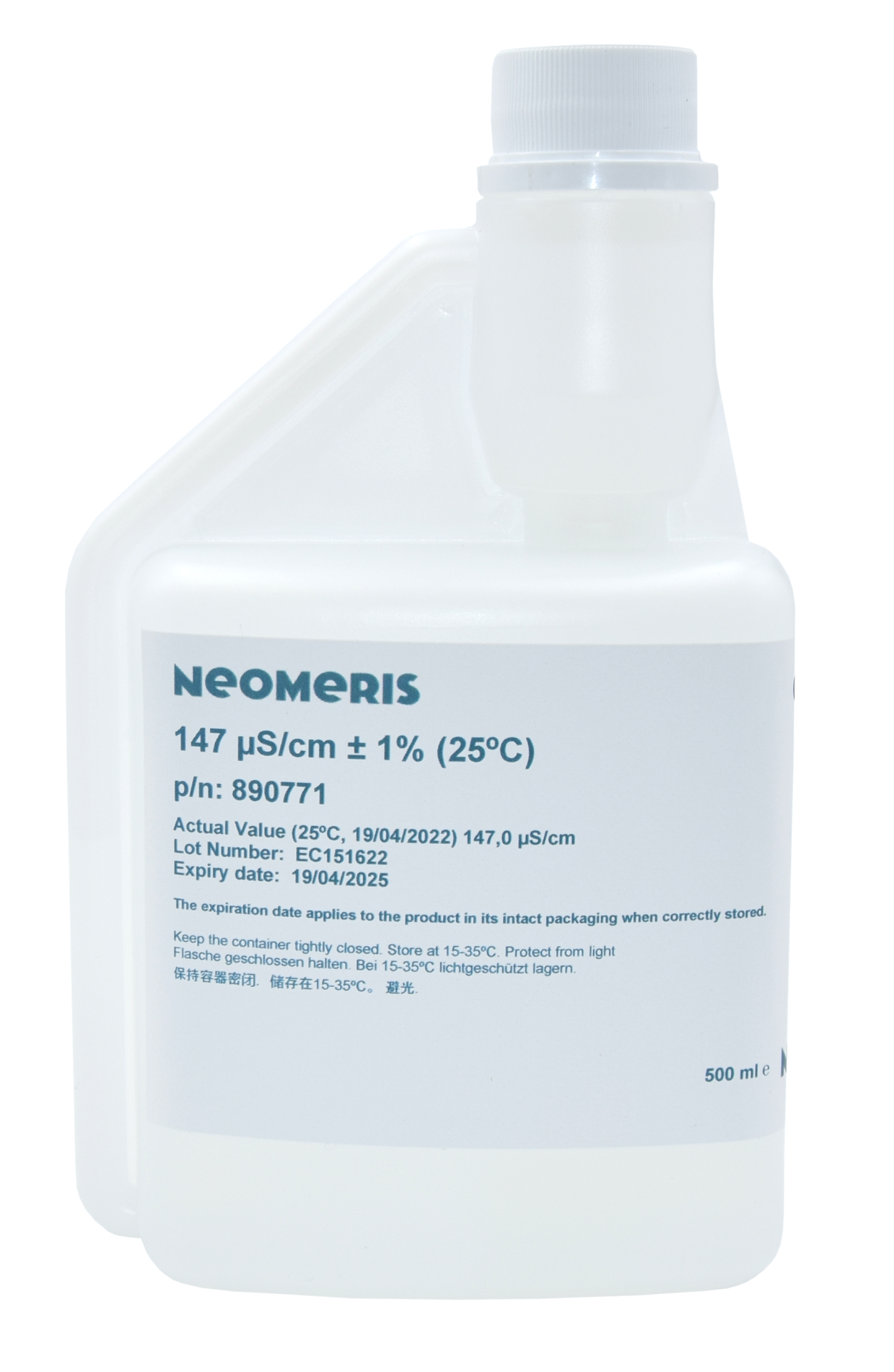

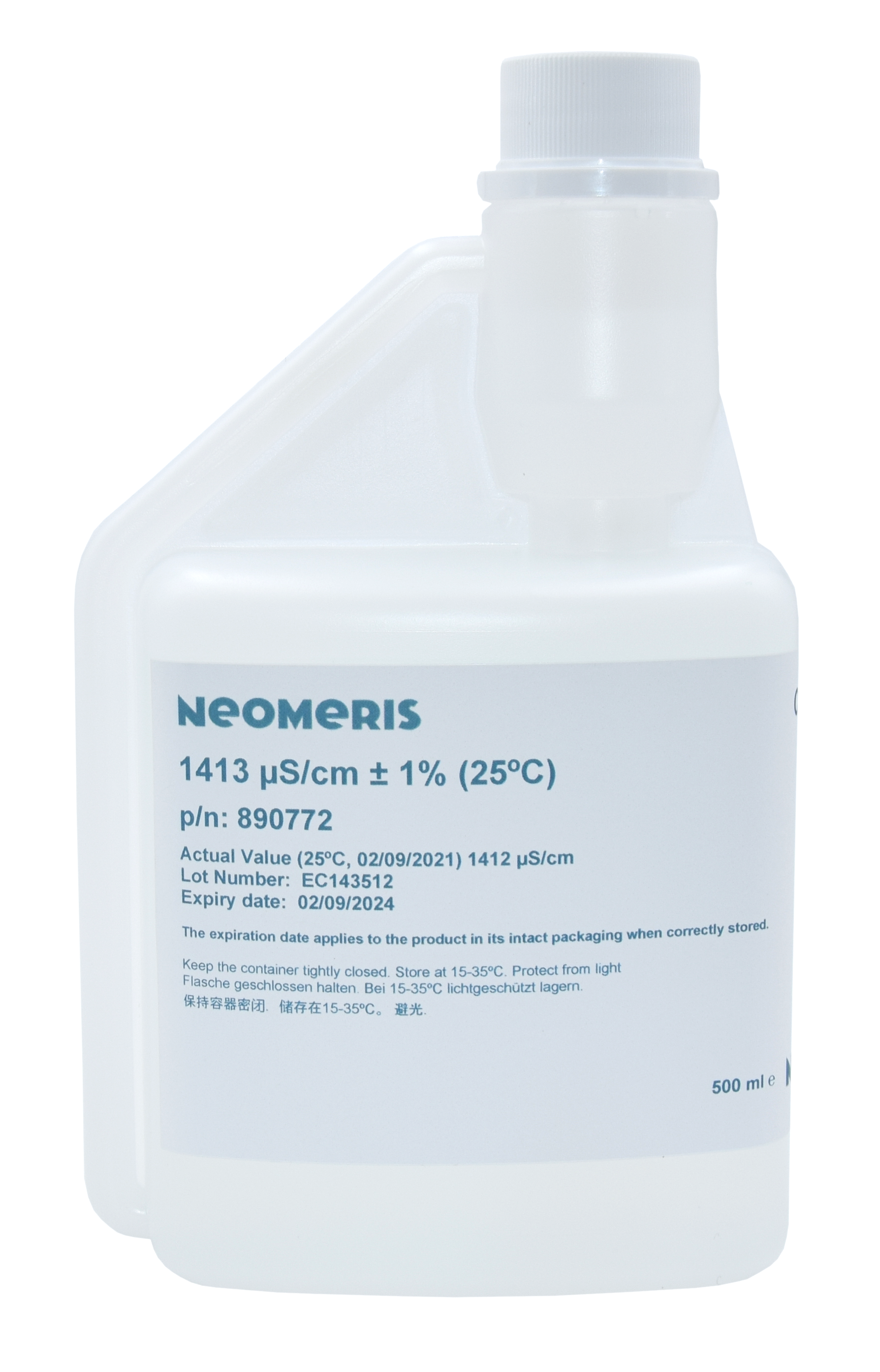

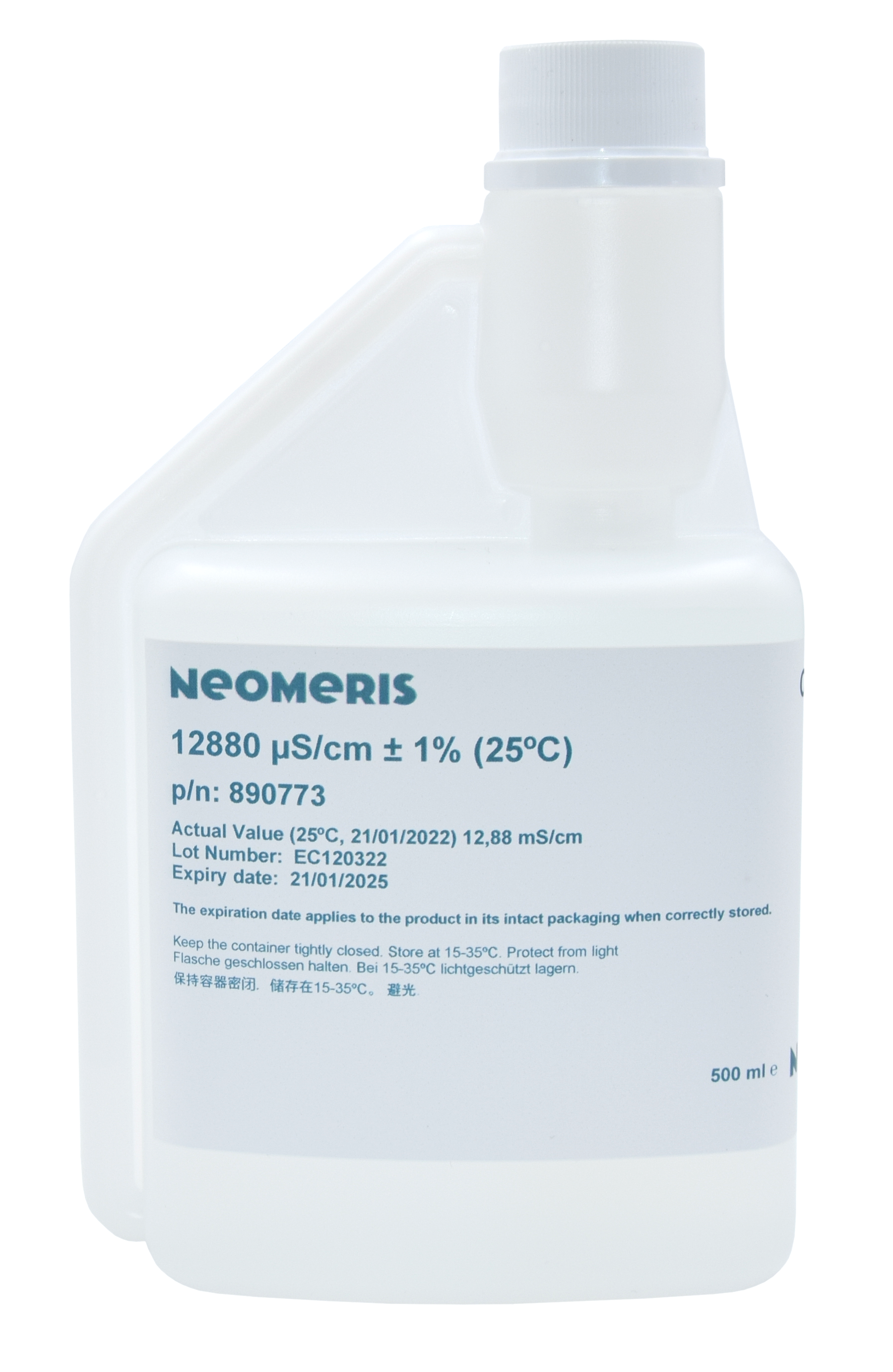

The conductivity depends not only on the salt concentration but also on the temperature. When calibrating the system, care must therefore be taken to ensure that a reference solution produced in accordance with international standards is used. These are available in different concentrations. The manufacturers specify the conductivity for these solutions taking into account the media temperature. During calibration, care must be taken to ensure that the probe first remains in the medium for some time in order to adapt to the temperature. Then the calibration is carried out on the value specified by the manufacturer for the measured temperature.

Calibration solutions are used by technicians in the course of system maintenance. They can be used to check the measurement accuracy of the conductivity probe and calibrate the system accordingly. These are aqueous potassium chloride solutions with known conductivity values. According to their properties, calibration solutions can be divided into primary, secondary and working solutions. Primary reference solutions have the lowest uncertainty of conductivity values (U(J) = 0.03 %). They are mainly used in the scientific environment. Secondary reference buffer solutions have the same composition of primary solutions. The uncertainty of the conductivity values is U(J) = 0.12 %. Working reference solutions are solutions for practical use; their uncertainty depends on the manufacturer, but should be in the range of U(J) ±0.4 % to U(J) ±1 %.

Conductivity measurements are important in many areas of technology and environmental protection. Depending on the application, the measurement takes place in the laboratory, with a handheld device on site or continuously, e.g. in the process.

A frequent application in the industrial environment is the monitoring of so-called mixed bed ion exchangers. If the resin (cation and anion exchange resin) contained therein is exhausted or nearing exhaustion, the dissolved salts are no longer completely retained and as a result the conductivity increases again. In this case, monitoring is carried out for a process-defined limit value. If this is exceeded, the filter concerned must be replaced.

Another classic area of conductivity monitoring is desalination in the cooling tower. Depending on the design of the overall system and the technical performance data, the evaporation of the circulating water causes a concentration of the dissolved substances. This is accompanied by an increase in conductivity. If this reaches the maximum value set for the system, the limit relay assigned to the measured value is switched and the so-called desalination is initiated.